In the world of branded merchandise, there are various different processes that can be used to apply your logo or messaging – and add that special sparkle to your chosen promotional products.

Some you may be familiar with, and some less so, but what do all these terms mean? What do the processes involve and which products can be branded in which ways to gain the optimum finish?

In this blog, our Sales Manager Emma Rawlinson, who has recently successfully completed her BPMA Trained in Promotional Merchandise certification, has put together a useful overview to explain some of the most popular processes and how or where they might be used.

Printing

There are four main types of printing commonly used to apply logos and messaging to a wide range of merchandise, from bottles or balloons to pens or pads. And with increasing demands for sustainable and eco-friendly merch, it’s not just manufacturing materials and processes that are stepping up to the mark, but we are also seeing a growing range of vegan inks and emulsions becoming available too.

So, what are the different processes?

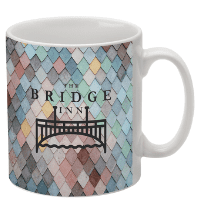

Screen printing, as the name suggests, uses a fine mesh screen to apply a design to a ‘flat’ surface, such as a bag or a mug. The ink is pressed through the screen and the image is gradually built up, with one colour being applied at a time.

Screen printing, as the name suggests, uses a fine mesh screen to apply a design to a ‘flat’ surface, such as a bag or a mug. The ink is pressed through the screen and the image is gradually built up, with one colour being applied at a time.

Pad printing also builds up an image one colour at a time, by applying inks with a rubber stamp called a pad. Unlike screen printing, pad printing is used for shaped surfaces, such as water bottles or pens.

Pad printing also builds up an image one colour at a time, by applying inks with a rubber stamp called a pad. Unlike screen printing, pad printing is used for shaped surfaces, such as water bottles or pens.

Transfer printing involves the application of branding using a printed transfer, which is ‘stuck’ to the chosen surface by using a heat press. Unlike screen or pad printing, transfer printing is ideal for photographic images. It can be used for difficult or hard to reach shapes or areas and is also a cost-efficient option for short runs.

Transfer printing involves the application of branding using a printed transfer, which is ‘stuck’ to the chosen surface by using a heat press. Unlike screen or pad printing, transfer printing is ideal for photographic images. It can be used for difficult or hard to reach shapes or areas and is also a cost-efficient option for short runs.

Dye sublimation printing also uses a heat transfer process but in this case, the product actually absorbs the design, so it is highly durable. Dye sublimation is great for textiles and soft surfaces (such as lanyards, wristbands or T Shirts), but can also be applied to some hard surfaces too, like glass or ceramics.

Dye sublimation printing also uses a heat transfer process but in this case, the product actually absorbs the design, so it is highly durable. Dye sublimation is great for textiles and soft surfaces (such as lanyards, wristbands or T Shirts), but can also be applied to some hard surfaces too, like glass or ceramics.

Embroidery

Embroidery is used on textiles and clothing, so anything from polo shirts to caps, towels or sports bags. Just like the traditional craft, a machine will use needles and thread to stitch your logo or branding onto each item. Costs for embroidery are based on a literal stitch count and it is suitable for single or multiple coloured logos. Innovation in terms of sustainability and eco-friendly materials is also apparent here, for example a special thread made from re-cycled plastic bottles.

Engraving

The engraving process uses a laser or a sharp instrument to etch a design on an item, producing a permanent finish. Engraving can be applied to hard materials such as glass, wood and metal, so it’s ideal for items such as badges, some pens, certain drinkware or even trophies. In addition, rotary engraving machines can roll an item, meaning that engraving can also be used for non-flat or curved surfaces.

Embossing and Debossing

Embossing and Debossing

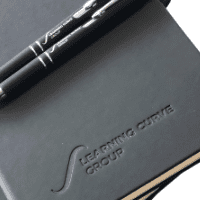

We’ve coupled these together as the end results are the exact opposite of each other.

Debossing uses a heated metal stamp, or die, to leave a recessed impression of a logo or marque onto the surface of an item. By contrast, embossing produces a raised result, so it physically stands out from the surface, although as the die is applied to both sides of a surface, it isn’t suitable for pre-produced items. Both processes deliver a great tactile finish to items ranging from soft cover notebooks to leather bags.

Foil Blocking

Foil Blocking

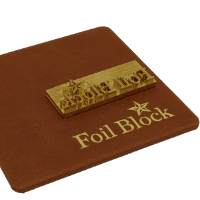

Foil blocking uses a similar method to debossing, but the main difference is the addition of colour, which is achieved by using a colour foil between the die and the merchandise. Metallics such as bronze, silver and gold are always popular choices for a luxury touch.

As you can see, the image you want to apply and the product you choose both play a big part in determining the perfect process, but your branding partner should always be able to advise you and guide you through your different options, so you get the final result you want.

And if you’d like to see some of these processes in action, then take a look and subscribe to our YouTube channel.